Squalo carbon monocoque confirmed as GTO Engineering continues to develop an all-new sub-1,000 kg, V12-powered production car

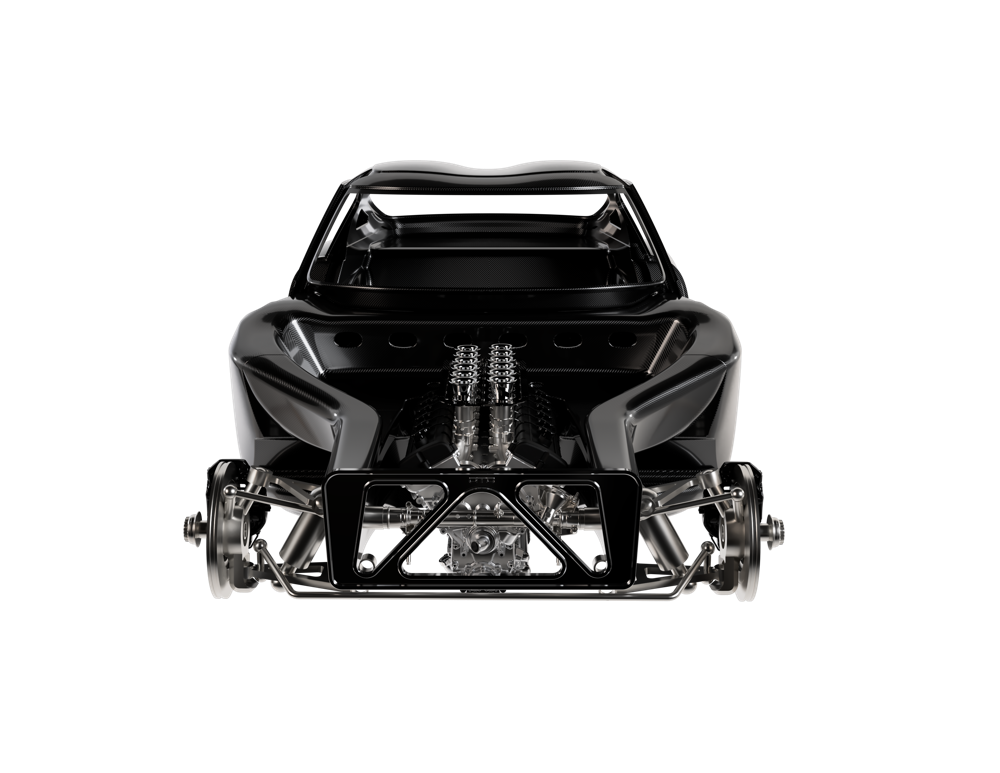

Striving to create a sub-1,000 kg, lightweight, driver-focused sports car, GTO Engineering has revealed, via 3D renderings, the first look at the all-new Squalo carbon fibre monocoque, created in conjunction with its latest technical partner, DEXET Technologies.

The partnership, which began in Q3 2021, has seen leading British composite design and engineering consultancy, DEXET Technologies, apply decades’ worth of Formula One and low-volume supercar production expertise to an all-new challenge: the sub-1,000 kg Squalo. The carbon fibre monocoque chassis possesses construction technology only seen thus far in the rarest of hypercars. The monocoque is designed to be manufactured in three parts for prime accessibility and maintenance. The forward section of the carbon monocoque chassis contains the engine and transmission, meanwhile the middle tub houses Squalo’s occupants, a brand new individually specified interior, and the fuel cell. The third, and one of the most innovative parts - the rear subsection - supports the rear suspension and power distributing differential. The three chassis subassemblies are bolted together to form a rigid structure, providing optimum feedback to the driver, with maximum precision.

Unlike GTO Engineering’s series of Revival cars, which in part use a donor vehicle for registration and sit on a period steel tube chassis, Squalo will be all-new and registered as a brand-new vehicle. As such, its team has been pushing technology and engineering to the limit as it approaches the vital testing of the monocoque and showing it to media and customers alike.

GTO Engineering’s in-house technical team – headed up by Chief Technical Officer, Alexander Aucken – has been working alongside DEXET’s design, material, and testing engineers, to combine their expertise and help deliver on GTO Engineering’s promise of a lightweight, two-door, narrow-packaged driver’s car homologated for major markets.

Francesco Aglietti, Founder and CEO of DEXET Technologies said: “The challenge of designing and developing this chassis using such cutting-edge composite construction has been a real privilege, and it’s incredibly exciting to be a part of such a distinguished project. GTO Engineering has allowed us to put our decades’ worth of Formula One and composite engineering experience to use and has trusted us with this key structural element with the primary focus, of course, being to achieve the coveted sub-1,000 kg kerb weight of Squalo. We are thrilled to finally see these plans coming to light by way of technical drawings and are looking forward to taking the next steps with the team at GTO Engineering.”

Alexander Aucken, Chief Technical Officer of GTO Engineering said: “Our goal was always to create something different and unique but keep to what we all fundamentally love about cars – the fun of driving them. By achieving the seemingly unachievable with the incredible team at DEXET Technologies, we will soon be able to offer a truly unique driver’s car. Squalo will be fully customisable to individual specifications, perfectly blending the style and atmosphere of the golden age of sports cars with ground-breaking modern technology, engineering and stimulating engine performance. It will be the ultimate bespoke collector car and we can’t wait to show the public what we’ve been working on. Squalo could not be produced without the vital input and expertise of DEXET Technologies. Watch this space.”

Both GTO Engineering and DEXET Technologies are currently working to achieve the next milestones. Defining and freezing the ergonomics of the interior using the recently revealed 3D-printed Squalo buck is the next immediate step, which will further allow DEXET to complete the design of the central carbon fibre tub. Once all the structural parameters are set, the engineers at DEXET will analyse the full chassis and bodywork with finite element analysis (FEA) and computational fluid dynamics (CFD) software. FEA gives engineers the ability to inflict real-world stresses and strains onto the computer-designed chassis model, allowing the team to modify, hone and perfect the digital version before creating something physical. CFD on the other hand will show how fluid, air for example, will flow over the bodywork, giving GTO Engineering and DEXET Technologies real insight into Squalo’s aerodynamic performance.

All enquiries regarding the Squalo are to be directed to [email protected], or call +44 (0) 118 490 1101 to discuss the delivery, specification, and individual ordering process with the team.